|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EOS 3 srl

Via G. Boccaccio, 18

20123 Milano - Italy

phones: +39 02/48008931

fax: +39 02/43912461

EOS 3 Bejing

Jingtai Tower,

24 Jianguomen Wai Street

Chaoyang District

Bejing (P . R . China)

phone: +86 1065156483

fax: +86 1065156484

|

|

|

|

| > Eos 3 > Best Alloy >

Diamond wire drawing die blanks |

|

|

|

Diamond wire drawing die blanks |

|

|

| |

|

|

| |

|

|

|

The diamond wire drawing die blanks are

polycrystalline diamond (PCD) products made under

high temperature and ultra-high pressure.

The components of PCD are diamond powder and a metal

catalyst (cobalt) sintered together. They have not only

high wear resistance, hardness and thermal

conductivity but also high mechanical strength and

tenacity.

Our diamond die blanks are a unique product

to draw a wide range of metals such as copper,

aluminium, nickel, nickel-chrome, steel, staniless

steel and special alloys.

We have two series of diamond wire drawing die blanks:

DW and TDW.

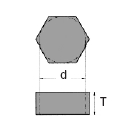

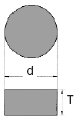

DW series are self-supported die blanks in two different

types: DWH (Hexagonal) and DWR (Round).

These blanks

are suitable for all kinds of wire drawing applications and

where a cost cutting is required.

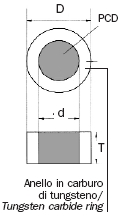

TDW series are tungsten carbide supported die blanks

with a polycrystalline diamond core integrally bonded to

a tungsten carbide ring.

This feature makes it suitable for

drawing with high intensity.

DW and TDW are available in 5 different grades of grain

size: 3, 5, 10, 25, 50 micron. |

|

|

|

Product code |

ADDMA*

Designa. |

Dimension (mm) |

Average Grain Size(µm) |

| Diameter |

diameter |

Thickness |

Note 2 |

|

|

|

|

|

| (mm) |

(mm) |

|

|

3 µm |

5 µm |

10 µm |

25 µ m |

50 µm |

|

Self supported Die Blanks (Hexagonal) |

| DWH 2510 |

D6 |

- |

2.5 |

1.0 |

0.4 |

o |

● |

● |

● |

- |

| DWH 3215 |

D12 |

- |

3.2 |

1.5 |

1.0 |

o |

● |

● |

● |

- |

| DWH 5225 |

D15 |

- |

5.2 |

2.5 |

1.5 |

o |

● |

● |

o |

- |

| DWH 5235 |

D18 |

- |

5.2 |

3.5 |

2.0 |

o |

● |

● |

o |

- |

| Drawing |

|

|

Self supported Die Blanks (Round) |

| DWR 2510 |

D6 |

- |

2.5 |

1.0 |

0.4 |

o |

● |

● |

o |

- |

| DWR 3215 |

D12 |

- |

3.2 |

1.5 |

1.0 |

o |

● |

● |

o |

- |

| DWR 5225 |

D15 |

- |

5.2 |

2.5 |

1.5 |

o |

● |

● |

o |

- |

| DWR 5235 |

D18 |

- |

5.2 |

3.5 |

2.0 |

o |

● |

● |

o |

- |

| DWR 8040 |

D21 |

- |

8.0 |

4.0 |

3.0 |

o |

● |

● |

o |

- |

| DWR 9853 |

D24 |

- |

9.8 |

5.3 |

4.0 |

o |

● |

● |

o |

- |

| DWR 13085 |

D27 |

- |

9.8 |

5.3 |

2.0 |

- |

- |

o |

● |

o |

| DWR 160120 |

D30 |

- |

5.2 |

3.5 |

2.0 |

- |

- |

o |

● |

o |

| Drawing |

|

|

Tungsten Carbide Supported Die Blanks |

| TDW 4015 |

D12 |

8.12 |

4.0 |

1.5 |

1.0 |

- |

o |

● |

● |

o |

| TDW 4023 |

D15 |

8.12 |

4.0 |

2.3 |

1.8 |

- |

o |

● |

● |

o |

| TDW 4029 |

D18 |

8.12 |

4.0 |

2.9 |

2.3 |

- |

o |

● |

● |

o |

| TDW 7040 |

D21 |

13.65 |

7.0 |

4.0 |

3.5 |

- |

o |

● |

● |

o |

| TDW 7053 |

D24 |

13.65 |

7.0 |

5.3 |

4.6 |

- |

o |

● |

● |

o |

| TDW 9070 |

D24 |

16.00 |

9.0 |

7.0 |

5.0 |

- |

- |

o |

o |

o |

| TDW 10080 |

D27 |

19.05 |

10.0 |

8.0 |

5.4 |

- |

- |

- |

o |

o |

| TDW 13075 |

D27 |

24.13 |

13.00 |

7.5 |

5.2 |

- |

- |

- |

o |

o |

| TDW 13086 |

D27 |

24.13 |

13.00 |

8.6 |

5.8 |

- |

- |

- |

● |

● |

| TDW 130116 |

D30 |

24.13 |

13.00 |

11.6 |

7.6 |

- |

- |

- |

● |

● |

| TDW 150120 |

D30 |

24.13 |

15.00 |

12.0 |

8.0 |

- |

- |

- |

o |

o |

| Drawing |

|

| |

|

|

|

|

|

|

|

|

|

|

* ADDMA:

American Diamond Die Manufacturers Association

Note 1

Die blanks must be cased below 650°C.

Note 2

The values reported in the table at Note 2 are the maximum

recommended die size for soft non ferrous alloys wire. For hard alloys

wire the diameter should not exeed 65% of this diameter.

● Die blanks on stock

o Die blanks on order

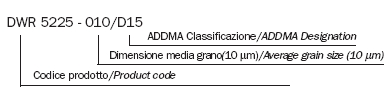

HOW TO ORDER

Typical order code

|

|

|

|

|

|

|

| |